The Craftsmanship Behind High-Quality Wooden Chess Sets: Excellence by Ningbo Shuangfan Plastic Manufacturing Co., Ltd.

The first step in our process is selecting the right wood, which forms the very foundation of a high-quality

wooden chess set. The wood choice directly impacts the overall aesthetic appeal, texture, and durability of the pieces. At Ningbo Shuangfan Plastic Manufacturing Co., Ltd., we understand that the type of wood used influences not just the look but also the feel of the game. We select a variety of premium hardwoods such as walnut, rosewood, maple, and ebony—each known for its unique properties. Walnut, for instance, provides a rich, deep brown color with a smooth texture that is ideal for both the chess pieces and the board. Rosewood, with its reddish-brown hue and striking grain patterns, adds a sophisticated touch, making it a favorite among collectors. Maple is chosen for its light color and fine grain, providing a bright contrast to darker pieces, while ebony is prized for its smooth texture and deep, dark hue, making it perfect for creating a high-contrast set that stands out. Each piece of wood is carefully inspected before we begin the crafting process. We prioritize selecting woods that are free of defects such as knots, cracks, or warping. This ensures that the final product is not only beautiful but also durable. After selection, we allow the wood to acclimatize to the workshop environment to prevent any shrinkage or expansion that could affect the integrity of the set.

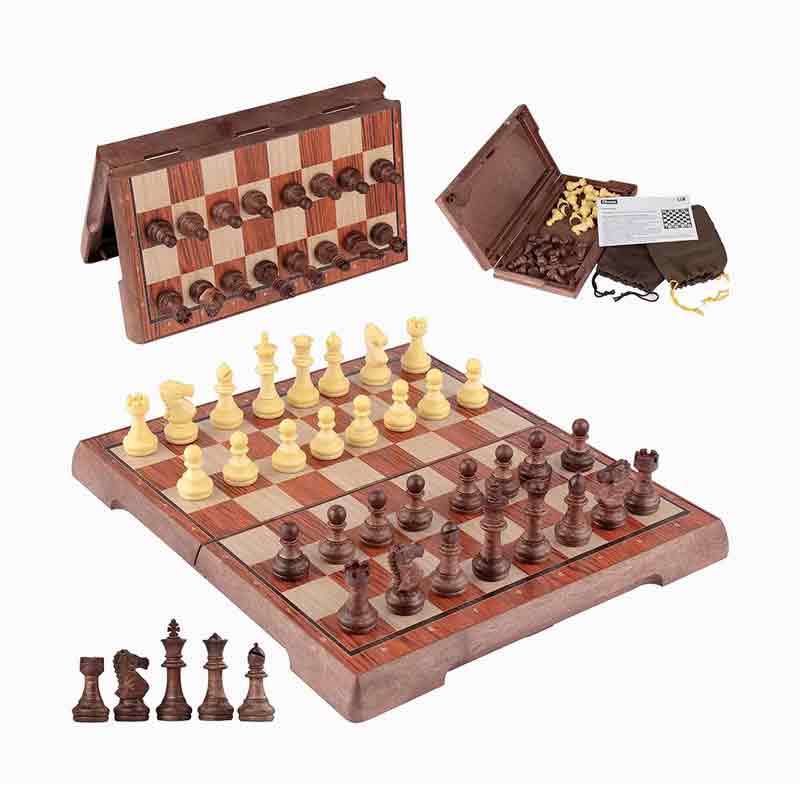

After selecting the wood, the next step is shaping the individual chess pieces. This is where our artisans’ skills truly shine. The pieces are first carved from solid blocks of wood, which requires both mechanical precision and the delicate touch of skilled hands. While modern machinery assists with initial cuts and shapes, much of the fine detailing is done by hand. This allows us to achieve the perfect proportions, weight, and balance for each piece. We begin by defining the basic shape of each piece. The king, queen, rooks, bishops, knights, and pawns are each shaped according to their traditional design, with subtle adjustments made to improve both their functionality and appearance. We carefully carve the contours and edges of each piece, ensuring that every curve flows smoothly and every detail is clear and well-defined. Each knight, for example, is sculpted with fine features that make it instantly recognizable and distinct from the other pieces. The bishop's mitre and the rook’s tower are crafted with attention to symmetry, while the king and queen’s crowns are designed with just enough flourish to add elegance without sacrificing balance. This is why we pay close attention to the ergonomics of the design. The pieces are shaped with a comfortable grip in mind, ensuring that players can easily handle and move them during gameplay. The careful carving ensures that no piece feels too light or too heavy—every chess piece is designed for balance and ease of movement across the board.

Once the pieces are shaped, the next critical step in the process is the finishing. The finish we apply to each piece not only enhances the wood’s natural beauty but also protects it from wear and tear, ensuring that the chess set remains in top condition for years. At Ningbo Shuangfan Plastic Manufacturing Co., Ltd., we use a variety of finishing techniques to bring out the best in the wood. Depending on the type of wood used, we apply the appropriate finish that complements its grain, texture, and color. For dark woods like rosewood and ebony, we typically apply a high-gloss finish that enhances the depth and richness of the natural grain. This glossy surface provides a smooth, polished look while also protecting the wood from scratches and fading. For lighter woods like maple and walnut, we use a matte or satin finish to maintain the natural, understated beauty of the wood. The matte finish highlights the wood’s texture without adding an overpowering shine, giving the chess set a classic, refined look. The finishing process is meticulous, as it involves several layers of polish and buffing. Each piece is carefully coated and allowed to dry before being sanded to achieve a smooth, even surface. This step is important because it ensures that the pieces feel smooth to the touch and free from any imperfections that could affect the gameplay experience. We also pay attention to the surface of the chessboard, ensuring that it is smooth, level, and free from defects. The finish on the board complements the pieces, creating a harmonious overall look.

When it comes to wooden chess sets, one of the most important factors is balance. A well-balanced set not only feels good to play with but also ensures that the pieces move smoothly on the board without tipping over or being too light to control. At Ningbo Shuangfan Plastic Manufacturing Co., Ltd., we take extra care to ensure that the weight and symmetry of each piece are consistent. Every chess piece is carefully weighed and adjusted to ensure that it sits comfortably on the board and provides a satisfying playing experience. We understand that the king and queen, which are the tallest pieces on the board, must be perfectly balanced to avoid toppling over during gameplay. Similarly, the pawns must be light enough to be easily moved but sturdy enough to stand upright during the game. We achieve this balance by carefully adjusting the weight of the pieces, either by carving out excess wood or adding weight to the base of each piece. This ensures that every piece performs well on the board and contributes to a smooth game experience. Symmetry is also a crucial element of our design. Each chess piece is crafted to be symmetrical, with uniform dimensions and proportions. This not only gives the set a clean, organized appearance but also ensures that the pieces are easy to distinguish from one another during gameplay. The knights, for example, are carved with careful attention to detail, ensuring that their facial features and body proportions are symmetrical and balanced. This level of precision extends to all the pieces, allowing them to be both beautiful and functional.

We place immense importance on quality control at every step of the production process. After each chess set is completed, it undergoes a thorough inspection to ensure that it meets our high standards. We inspect both the chess pieces and the chessboard for any defects, such as cracks, imperfections in the wood, or inconsistencies in the finish. Each piece is also tested for balance and weight to ensure that it moves easily and comfortably during gameplay. Durability is another key focus of our quality control process. We understand that a chess set is an investment, and we want to ensure that our products stand the test of time. We test the durability of the finish to ensure that it won’t fade, scratch, or peel with regular use. The chessboard is also checked for stability, ensuring that it remains level and sturdy for years of use.

English

English Deutsch

Deutsch Español

Español