-

Double 6 Dominoes vs. Double 12 Dominoes: The Foundations of Tile-Based Gaming Dominoes, affectionately referred to by enthusiasts as bones or stones, have evolved over centuries into a rigorous system of specifications. While modern manufacturing has transitioned materials from ivory and ebony to high-density resin an...

READ MORE -

Double 6 Dominoes: The Timeless Classic and Spirit of Competition 1. Entering the World of Double 6 Dominoes In the long history of board games, few titles carry as much cultural heritage and modern vitality as Double 6 Dominoes. A standard Double 6 Dominoes set consists of 28 tiles, each referred to as a "tile" or "bo...

READ MORE -

In the professional community of Double 9 Dominoes, the choice between Mexican Train and Chickenfoot dictates the logical depth and social tempo of the match. While both belong to the blocking games category and revolve around the mathematical probabilities of a 55-tile set, their core mechanisms shape the topology of ...

READ MORE

What are the common processes for dominos set for adults?

Q: What are the most common materials for making adult dominoes?

A: In the adult market, common materials for dominoes include ABS plastic, resin, wood, and the particularly important urea-formaldehyde resin (Urea Resin). Among them, urea-formaldehyde resin has become the preferred material for high-end adult domino sets due to its stiff texture, high wear resistance, and fine grinding and carving.

Ningbo Shuangfan Plastic Manufacturing Co., Ltd. has been focusing on the development and production of urea-formaldehyde dominoes for many years. As early as 2008, it established its own mold workshop with rich experience in urea-formaldehyde material formulation and process adjustment to ensure that the dominoes reach the industry-leading level in appearance, feel and durability.

Q: What role does the molding process play in the quality of dominoes?

A: The molding process of dominoes is usually divided into two types: injection molding and compression molding. Adult dominoes have higher requirements for surface flatness and edge sharpness, so precision molds are often used in combination with injection molding to achieve consistency and high-density structure.

On Ningbo Shuangfan's production line, we have independently developed and continuously optimized a variety of high-precision molds to meet customized production requirements of different specifications, thicknesses and chamfers. Our production equipment has high-temperature and high-pressure injection molding capabilities to ensure that there are no quality risks such as bubbles and cracks during the molding process of dominoes.

Q: How are the patterns or points on the surface of dominoes made?

A: The production method of domino points is a key factor affecting the service life and aesthetics. Common processes include:

Silk Screen Printing: Suitable for mass production, mature technology, and a variety of colors.

Laser Engraving: Suitable for high-end dominoes, with consistent engraving depth and not easy to fade.

In-Mold Coloring: Integrate colors during the molding stage, prevent shedding, and have strong wear resistance.

Hand-Painting: Used for customized or artistic products, emphasizing personalization and uniqueness.

At Shuangfan, we provide a variety of process options for different levels of customer needs, especially in laser engraving and in-mold color injection. We have accumulated mature mass production experience, which can not only meet the high-end market's pursuit of texture, but also achieve low-cost and efficient industrial production.

Q: What are the requirements for packaging technology for adult domino sets?

A: Adult customers pay more attention to the overall experience, so packaging technology is also part of the product value. Common packaging options include:

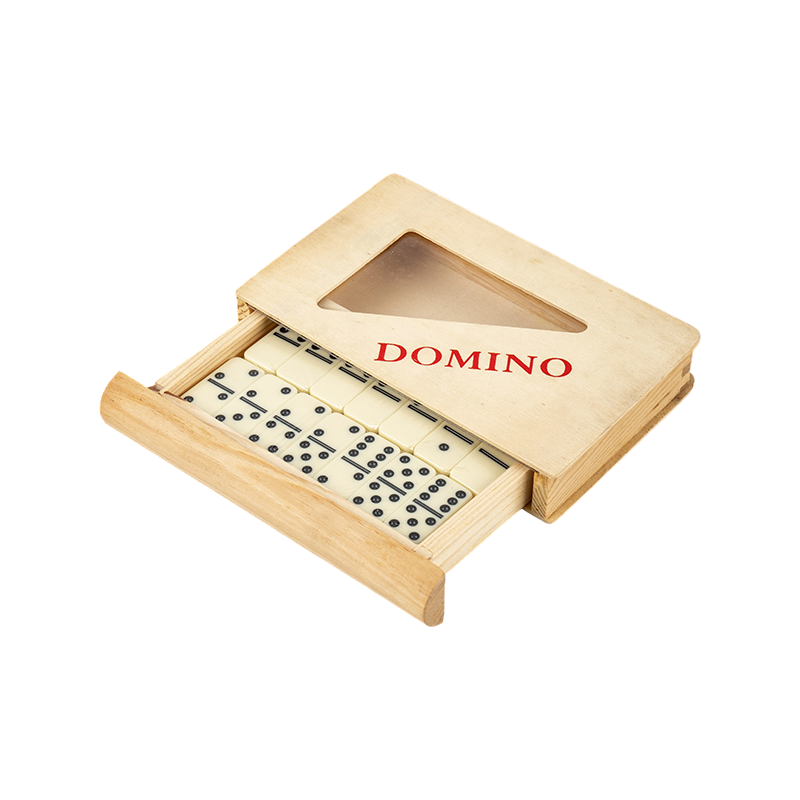

High-end wooden box packaging (such as walnut, birch)

PU leather box, magnetic box design

Personalized hot stamping LOGO and customized label

Environmentally friendly paper box packaging to meet the sustainable requirements of overseas markets

Ningbo Shuangfan has a complete packaging chain cooperation system. We can provide one-stop supporting services from structural design, LOGO customization to final shipment according to the brand requirements of B2B customers. At the same time, our packaging materials meet international environmental standards and are easy to export to Europe, America, the Middle East and other regions.

Q: What are your company's unique advantages in adult domino technology?

A: As a professional manufacturer established in 2008, Ningbo Shuangfan Plastic Manufacturing Co., Ltd. has more than 100 experienced employees, among which the core staff of the domino production line have an average of more than 10 years of industry experience. Our unique advantages include:

Self-developed molds, full styles, and fast customization

Focus on the production of urea-formaldehyde dominoes, with a texture superior to similar products

Introducing advanced injection molding and laser engraving equipment to ensure high-quality output

Strictly implement international safety and environmental standards and support third-party testing

Possessing mass production capabilities, short delivery cycles, and suitable for long-term B2B cooperation

What is the difference in mold precision between dominos set for adults and children's sets

Q: What are the fundamental differences in mold design between adult dominoes and children's sets?

A: Adult dominoes are usually used in social gatherings, collections, gifts and other scenes, so they have higher requirements for appearance consistency, smoothness of corner craftsmanship, and dimensional tolerance control. Children's sets emphasize safety, lightness and fun, and the dependence on mold precision during the manufacturing process is relatively low, but they will focus on anti-collision design, rounded corners and color vividness.

As a manufacturer specializing in the production of urea-formaldehyde dominoes, Ningbo Shuangfan Plastic Manufacturing Co., Ltd. has been independently developing domino molds since 2008, and currently has dozens of mold systems for different markets and age groups. We are well aware that mold accuracy not only affects the appearance of the product, but also directly determines the sense of assembly and user experience of the finished product.

Q: Specifically, what key role does mold accuracy play in adult dominoes?

A: In adult dominoes, mold accuracy is mainly reflected in the following aspects:

Dimension tolerance control: Adult dominoes usually require the length, width and thickness of each domino to be within ±0.1mm, otherwise it is easy to tilt or be unstable during stacking and arrangement.

Edge angle consistency: Advanced dominoes are particularly particular about edge grinding, and chamfers should be smooth and without sharp edges, while maintaining consistency. The angle tolerance of the mold usually needs to be controlled within ±0.5 degrees.

Point number groove depth accuracy: Adult models often use laser engraving or mold engraving concave points. The depth of the groove affects the color uniformity and visual beauty, so the mold cavity must be highly refined.

Surface texture treatment: Some high-end dominoes need to present matte, frosted or mirror effects, which require special treatment or electroplating of the mold surface to achieve better visual texture.

In Shuangfan's mold manufacturing workshop, we have introduced high-precision CNC machining centers and imported EDM equipment to ensure that the machining accuracy of each set of molds meets strict standards and create dominoes with exquisite texture for adult market customers.

Q: Why do children's dominoes have lower requirements for mold accuracy? Will this affect the use effect?

A: The focus of the design of children's dominoes is safety, fun and resistance to falling and hitting. Therefore, the mold structure will pay more attention to:

Rounded corners to avoid scratches;

Lightweight, easy for children to operate;

Rich colors, conducive to attracting attention.

Under this positioning, small errors in size and angle have little effect on the overall experience, so the mold accuracy standard will be slightly lower than that of adult models, and the general size tolerance is acceptable between ±0.2~0.3mm.

In Shuangfan's children's product line, we use a specially thickened mold cavity design to ensure that the product has good pressure resistance, and use food-grade safe raw materials with environmentally friendly coatings to fully meet the toy safety certification requirements of the European and American markets.

Q: How does your company control mold accuracy in actual production?

A: This involves full process management from mold design, processing, mold trial to mass production. Specific measures include:

Design stage: experienced engineers use 3D modeling software (such as UG, SolidWorks) to design precision molds;

Processing stage: imported equipment is used to process parts with an error control of 0.01mm;

Mold trial stage: multiple rounds of trial production and process verification are carried out, and key parameters such as size, corners, and concave points are fully inspected;

Mass production stage: mold maintenance and adjustment are arranged before mass production to ensure the consistency and stability of each batch of products.

Our mold engineering team has more than 10 years of industry experience. Each set of molds will undergo three process quality inspections before delivery for production, striving to deliver perfect domino products to customers.

Q: What does this accuracy difference mean to B2B customers?

A: For B2B customers, mold precision means:

Adult models: higher product added value, stronger market competitiveness, and higher customer repurchase rate;

Children's models: more controllable costs, more flexible shipments, and a wide range of consumer markets.

Ningbo Shuangfan Plastic Manufacturing Co., Ltd. is able to design customized mold systems for adult models and children's models according to the target market and consumer groups required by customers, achieving stable batch supply, rapid response and adjustment, and consistent and controllable quality. This is one of our core capabilities to win the trust of overseas customers for a long time.

Amazing Together

English

English Deutsch

Deutsch Español

Español